When discussing optical transceivers, one term frequently appears in both datasheets and engineering conversations: DDM in optical modules. Many engineers rely on it every day, yet newcomers often wonder what it really means and how it benefits network operations. Let’s break it down in a practical way.

What is DDM in Optical Modules?

DDM stands for Digital Diagnostic Monitoring. In optical modules, DDM enables real-time monitoring of critical parameters such as optical output power, input power, laser bias current, module temperature, and supply voltage. In essence, DDM in optical modules acts like a “health monitor” that continuously checks device conditions and provides feedback to the system.

Why is DDM in Optical Modules Important?

Without DDM, diagnosing optical link issues often requires external test equipment, which increases downtime and costs. With DDM in optical modules, network operators can immediately detect abnormal conditions, such as excessive temperature or low received optical power. This proactive monitoring allows quick troubleshooting, prevents unexpected failures, and supports predictive maintenance.

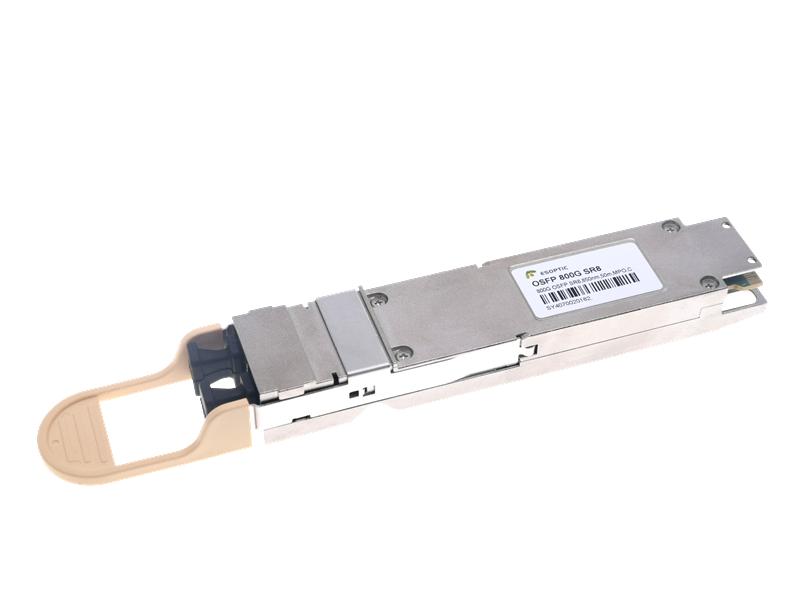

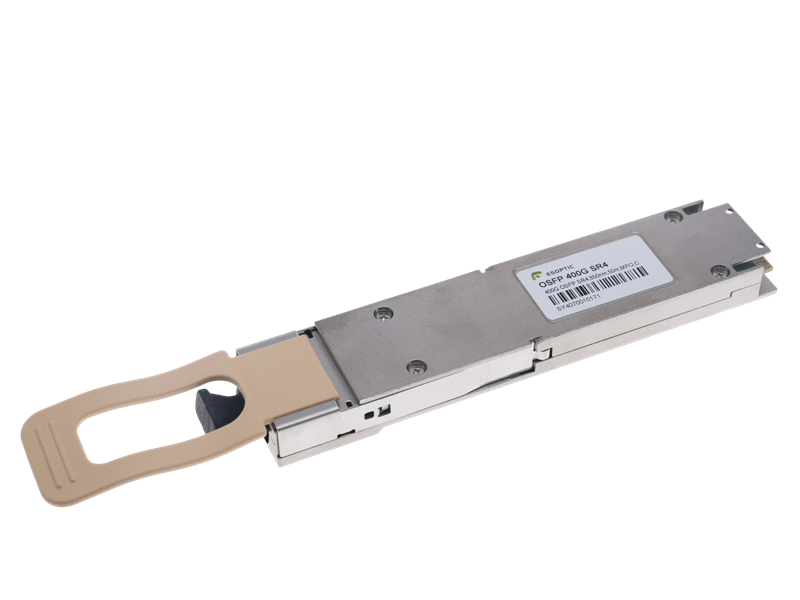

The ESOPTIC Approach

At ESOPTIC, all major optical modules are designed with robust DDM functions. Instead of treating DDM as a checkbox feature, ESOPTIC ensures that DDM in optical modules delivers accurate readings and stable reporting across different network environments. Our customers, from data centers to telecom operators, benefit from reduced maintenance costs and enhanced network visibility.

Beyond Numbers: How DDM Adds Value

DDM in optical modules is not just about numbers on a dashboard. It enables intelligent network management by allowing thresholds to be set for alarms and warnings. For example, if laser bias current begins drifting, DDM can alert operators before it impacts performance. This helps avoid unnecessary downtime and supports long-term reliability planning.

Conclusion

In modern high-speed networks, DDM in optical modules has become indispensable. By turning raw optical signals into actionable data, it empowers engineers to maintain stability, optimize resources, and extend module lifespan. At ESOPTIC, we view DDM as a key element in delivering dependable interconnect solutions.

FAQ

1. What parameters does DDM in optical modules monitor?

Temperature, supply voltage, bias current, transmit power, and receive power.

2. Does every optical module support DDM?

Not always. Most modern SFP, SFP+, QSFP, and higher-speed modules include DDM, but legacy designs may not.

3. How accurate is DDM in optical modules?

Accuracy depends on the manufacturer’s calibration. ESOPTIC ensures tight tolerance and reliable reporting.

4. Can DDM data be used for predictive maintenance?

Yes. By analyzing trends in temperature or bias current, operators can predict failures in advance.

5. How does ESOPTIC enhance DDM functionality?

Through rigorous testing, calibration, and integration with network monitoring systems, ensuring stable performance.