In modern high-speed networks, optical transceivers are the foundation of reliable data transmission. However, poor handling or improper procedures can lead to performance loss or permanent damage. This guide from ESOPTIC provides practical tips on optical transceiver insertion, removal, cleaning, and ESD protection, ensuring that your modules operate efficiently and safely.

🔌 Proper Optical Transceiver Insertion & Removal

Before installing an optical transceiver, always make sure the device is powered down (unless hot-swapping is supported), and your hands are clean and grounded.

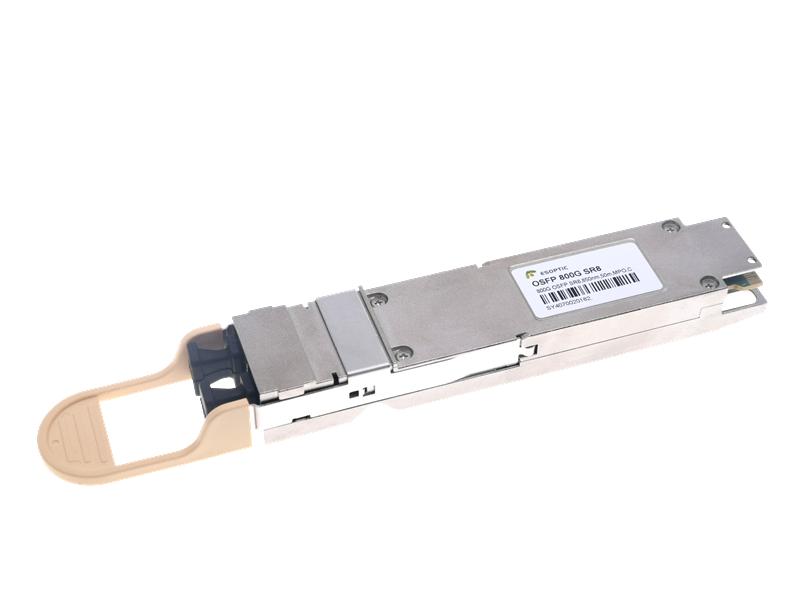

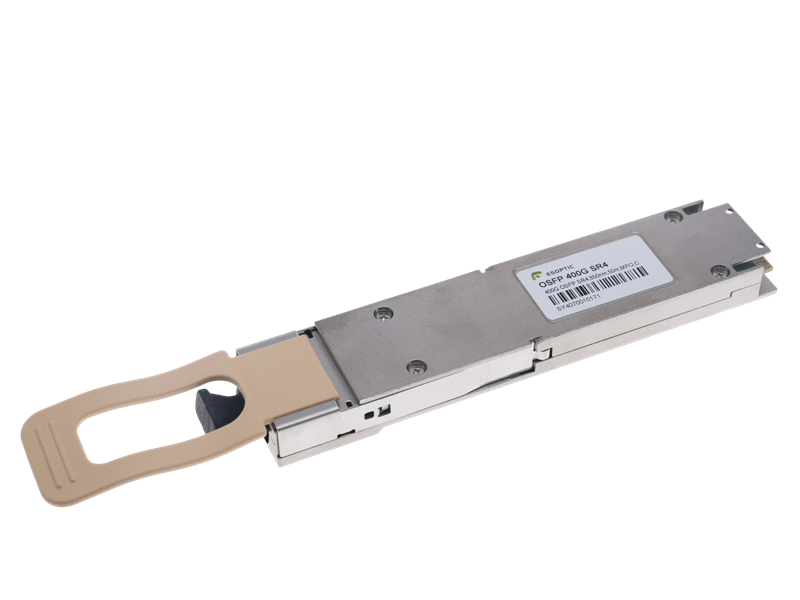

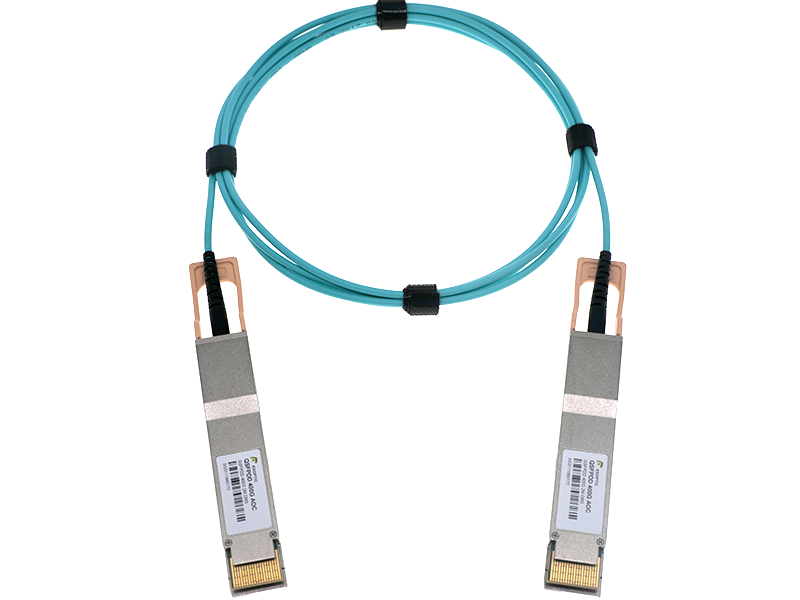

To insert the optical transceiver, align it with the cage and press gently until it clicks. Avoid forcing the module or inserting it at an angle. For removal, release the latch or pull-tab, then pull the optical transceiver straight out. Improper insertion and removal may damage the connector pins or cage.

ESOPTIC recommends using only compatible optical transceivers for your equipment to avoid mechanical and protocol mismatches.

✨ Cleaning Optical Interfaces

Contamination is a frequent cause of high insertion loss. Before connecting an optical transceiver, inspect and clean the optical interface using a fiber scope and a lint-free cleaner. ESOPTIC provides all modules with dust caps to protect the port during storage.

Do not touch the lens of the optical transceiver, and never use compressed air from your mouth to clean—it introduces moisture that may worsen the situation.

⚡ ESD Protection Measures

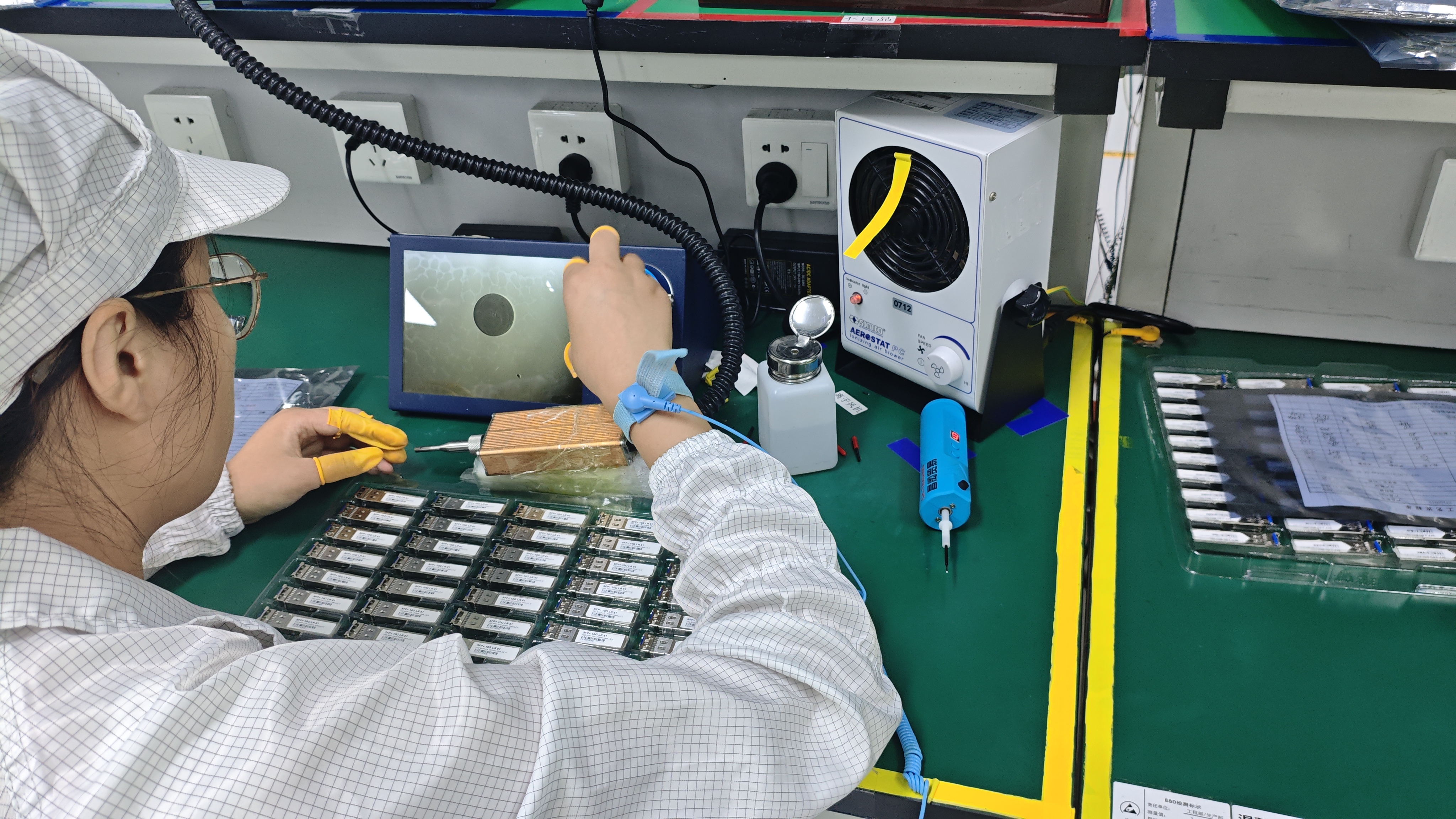

ESD protection is a critical yet often ignored part of optical module handling. Electrostatic discharge can damage the internal laser driver and digital signal processors.

Follow these ESD protection practices:

Always wear an ESD wrist strap grounded to an antistatic mat.

Handle optical transceivers in an ESD-safe area.

Use ESD-safe containers for storage and transportation.

At ESOPTIC, all optical transceivers are manufactured, tested, and packaged under strict ESD protection standards to ensure product reliability in sensitive environments.

🧰 Handling Tips

Label and track each optical transceiver installed in your system.

Avoid excessive insertions/removals to extend mechanical life.

Never use tools to force the optical transceiver into the cage.

Use only industry-standard cleaning tools before each connection.

By adopting the right handling techniques and enforcing strong ESD protection, your optical transceivers will deliver consistent performance with lower failure rates.

❓ FAQ – Optical Transceiver & ESD Protection

Q1: How do I know if my optical transceiver is ESD-damaged?

A: Symptoms include no output signal, abnormal power draw, or unresponsive behavior.

Q2: Can I hot-plug an optical transceiver?

A: Only if the system explicitly supports hot-swapping. Otherwise, power off the device first.

Q3: How often should I clean the transceiver interface?

A: Clean whenever you see signal degradation, or at least every 3-6 months.

Q4: What packaging does ESOPTIC use for ESD protection?

A: We use antistatic trays and ESD bags that meet IEC 61340-5-1 standards.

Q5: Why does ESOPTIC emphasize ESD protection so much?

A: Because even a small electrostatic discharge can destroy sensitive transceiver components, leading to premature failure.

With the right care, every optical transceiver becomes a reliable asset in your network infrastructure. Trust ESOPTIC for both quality and guidance in safe, high-performance optical connectivity—backed by tested ESD protection every step of the way.