As the boundaries between industrial automation and edge computing continue to blur, high-speed and low-latency data transmission has become the foundation of modern intelligent manufacturing. The optical module, once seen primarily as a data center component, is now playing an increasingly critical role at the industrial edge.

In traditional industrial environments, copper connections often face challenges such as signal attenuation, electromagnetic interference, and limited bandwidth. However, with the rapid rise of Industry 4.0 and the Industrial Internet of Things (IIoT), the demand for real-time data processing and reliable connectivity has grown exponentially. This is where optical modules come into play — bridging the gap between high-speed data networks and edge devices.

1. Optical Modules Empowering Industrial Automation

In modern factories, optical modules enable seamless data transmission between production lines, controllers, and monitoring systems. For example, robotic arms, motion sensors, and PLCs require precise synchronization and stable connections. Optical modules ensure high-speed, low-latency communication in these scenarios, greatly enhancing automation efficiency and production accuracy.

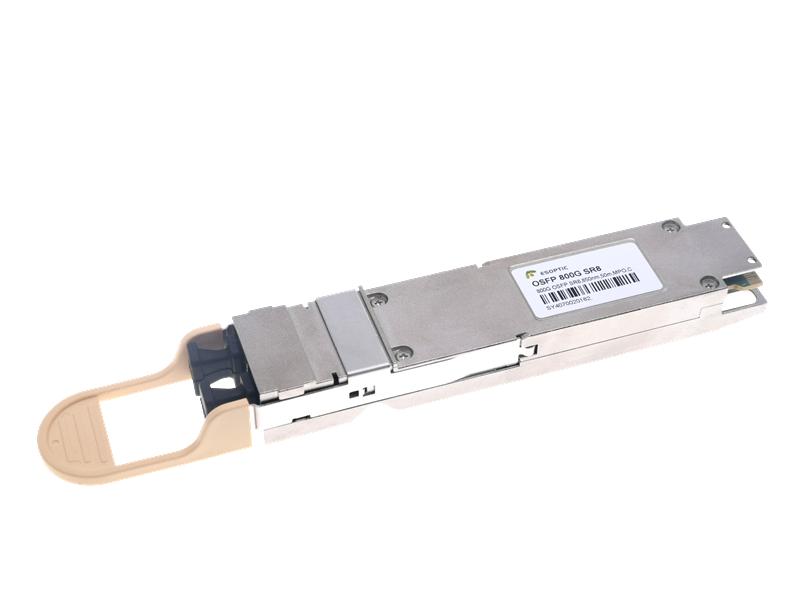

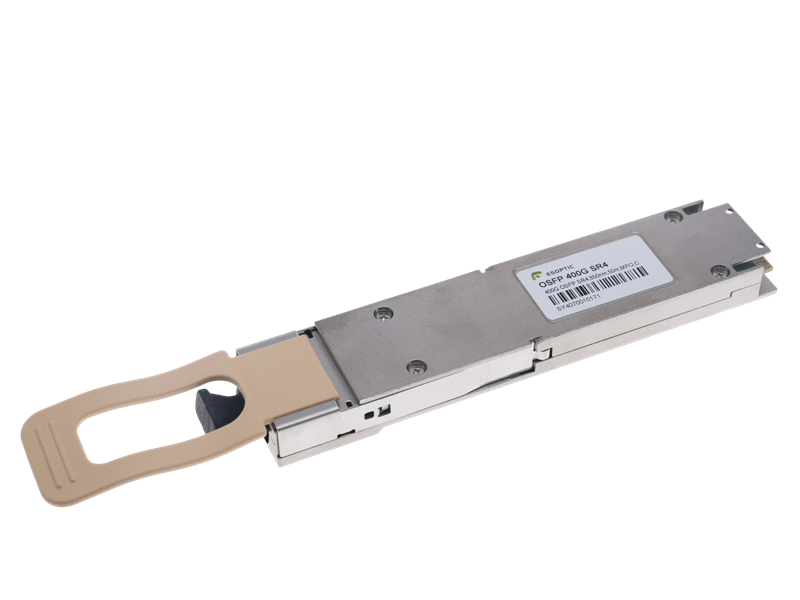

ESOPTIC’s high-reliability optical modules are designed with ruggedized housings, wide temperature tolerance, and industrial-grade components. They deliver consistent performance even in harsh environments with vibration, dust, or high humidity — ensuring stable data flow in critical automation systems.

2. Driving Edge Computing Connectivity

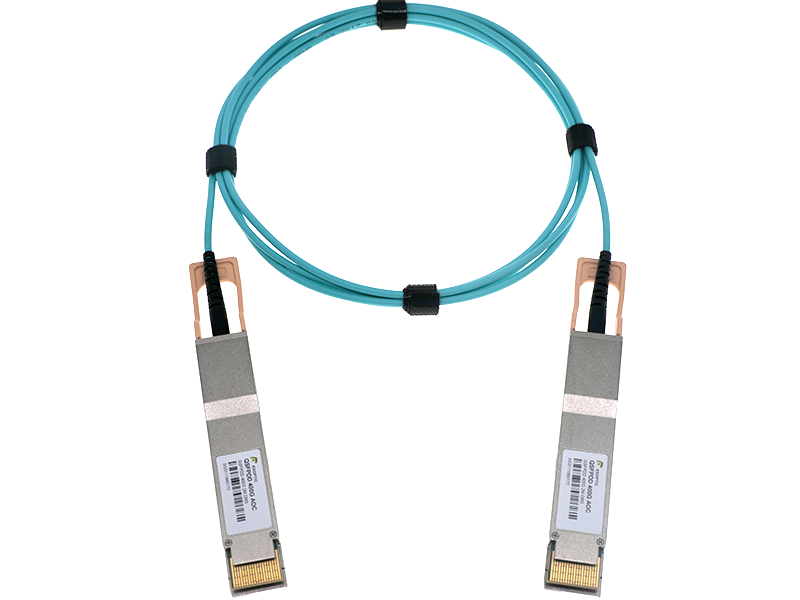

Edge computing brings processing closer to where data is generated, reducing latency and improving real-time response. Optical modules support this architecture by enabling fast interconnection between edge servers, gateways, and cloud systems. Whether in intelligent transportation, smart grids, or remote monitoring systems, optical modules ensure data is transferred efficiently and securely.

ESOPTIC’s 10G, 25G, and 100G industrial optical modules provide flexible transmission distances from a few meters to tens of kilometers, perfectly fitting the needs of distributed edge computing networks.

3. Energy Efficiency and Reliability

Compared with traditional copper cables, optical modules consume less power and offer higher bandwidth. This makes them ideal for large-scale edge deployments where power consumption and thermal control are key factors. ESOPTIC continuously optimizes optical transceiver design to enhance signal integrity while reducing energy loss — helping enterprises achieve both performance and sustainability goals.

FAQ

1. Why are optical modules essential in industrial automation?

They provide high-speed, interference-free data transmission crucial for real-time control and monitoring in automated systems.

2. Can ESOPTIC optical modules operate in harsh industrial environments?

Yes. ESOPTIC industrial-grade optical modules are designed to withstand wide temperature ranges, vibration, and dust.

3. How do optical modules improve edge computing performance?

They enable fast, stable connections between edge devices, servers, and cloud platforms, minimizing latency and maximizing reliability.

4. Are optical modules more energy-efficient than copper cables?

Yes. Optical modules reduce signal loss and power consumption while supporting higher data rates.

5. Which ESOPTIC products are suitable for industrial automation and edge computing?

ESOPTIC’s 10G SFP+, 25G SFP28, and 100G QSFP28 industrial series are ideal for factory automation, smart city, and edge computing networks.